Introduction

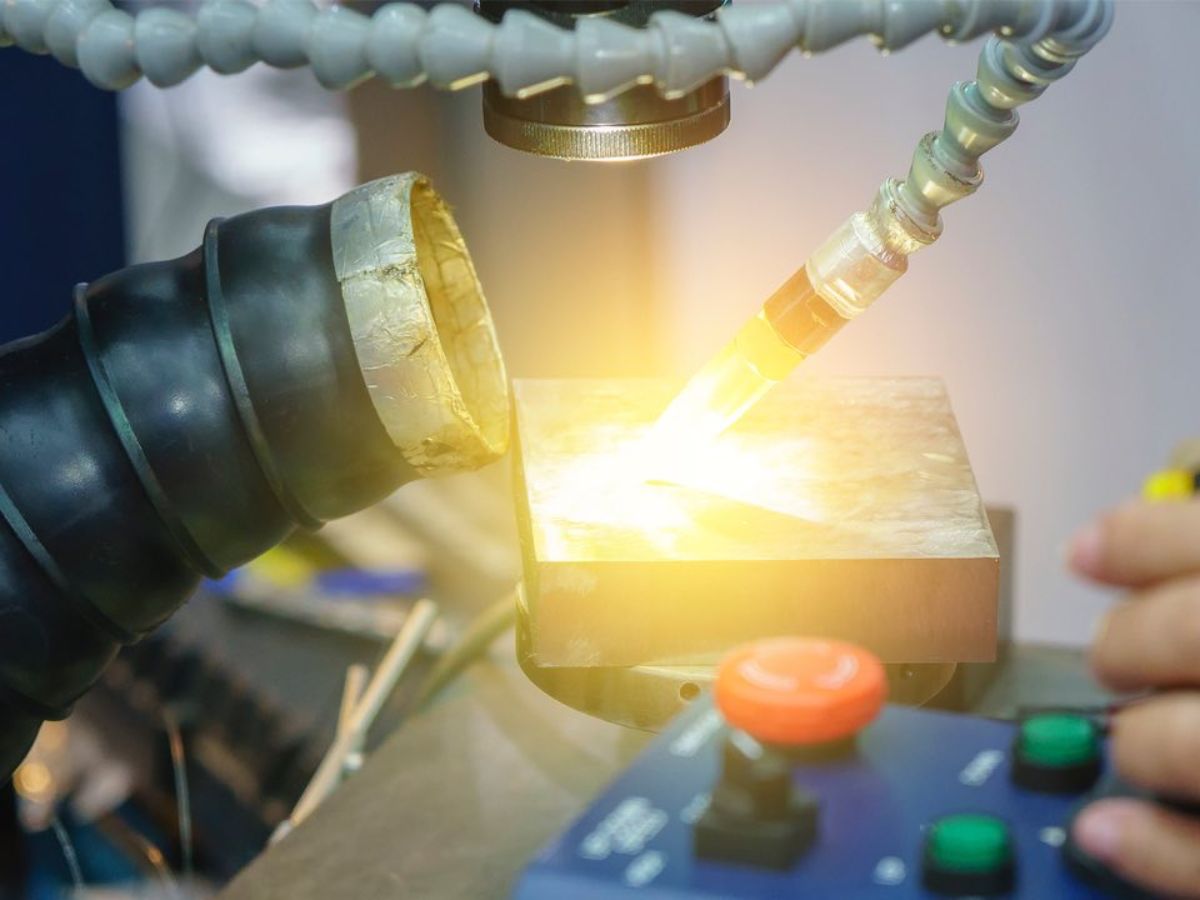

Welding is not just a job; it’s an art form that combines science and skill to create strong and durable joints between metals. Among the myriad of welding techniques available, arc welding stands out due to its versatility, efficiency, and reliability in producing high-quality welds. In this article, we'll explore various arc welding techniques that are essential for achieving stronger, more durable joints. We will also touch on related processes like MIG welding, TIG welding, and plasma welding, as well as delve into the importance of proper equipment and safety practices.

Arc Welding Techniques for Stronger, More Durable Joints

Arc welding employs an electric arc to melt the base metal and filler material simultaneously. This technique can be executed in several ways, each with unique benefits and applications. The goal is always the same: to produce a joint that can withstand stress, strain, and environmental factors over time.

Understanding Arc Welding

Arc welding makes use of electricity to generate heat. The electric arc forms between an electrode and the workpiece, melting both materials together. This process creates a molten pool that solidifies into a strong joint upon cooling.

The main types of arc welding include:

Shielded Metal Arc Welding (SMAW) Gas Metal Arc Welding (GMAW or MIG welding) Gas Tungsten Arc Welding (GTAW or TIG welding) Flux-Cored Arc Welding (FCAW) Submerged Arc Welding (SAW)Each type has its own set of advantages depending on the materials being welded, the environment, and the desired outcomes.

Types of Arc Welding Techniques

Shielded Metal Arc Welding (SMAW)

SMAW is one of the oldest forms of arc welding and involves a consumable electrode coated in flux. The electrode melts during the process while shielding gases protect the weld pool from contaminants.

- Advantages: Versatility on various metals Can be done outdoors Lower equipment costs Disadvantages: Slower than other methods Requires more skill to master

Gas Metal Arc Welding (MIG)

MIG welding employs a continuous solid wire electrode fed through a welding gun while xpress mobile welding Phoenix shielding gas protects the weld area from contamination.

- Advantages: Higher speed than SMAW Easier to learn for beginners Suitable for thin materials Disadvantages: Less effective outdoors due to wind affecting gas shield Requires more expensive equipment

Gas Tungsten Arc Welding (TIG)

TIG utilizes a non-consumable tungsten electrode to produce the weld while using a filler rod when necessary.

- Advantages: High-quality welds with excellent finish Versatile for different materials including aluminum and stainless steel Minimal spatter Disadvantages: Requires high skill level Slower process compared to MIG or SMAW

Flux-Cored Arc Welding (FCAW)

FCAW is similar to MIG but uses a tubular wire filled with flux instead of solid wire.

- Advantages: Good for outdoor conditions due to self-shielding options Faster than traditional MIG Disadvantages: Produces more smoke and fumes Equipment may be costly

Submerged Arc Welding (SAW)

In SAW, an arc forms beneath a blanket of granular flux which provides protection against contamination.

- Advantages: High deposition rates Deep penetration capabilities Disadvantages: Not suitable for all positions—mostly flat Limited visibility during operation

Choosing the Right Technique for Your Project

When deciding on an arc welding technique, consider these factors:

Type of Material: Different metals require specific techniques. Environment: Indoor vs outdoor can affect your choice. Joint Design: Complexity can dictate which method is more efficient. Budget: Some methods require significant investment in equipment.Essential Equipment for Effective Arc Welding

Having the right tools is crucial when it comes to producing strong joints through any arc-welding technique. Let's explore some essential equipment involved in this process:

1. Power Source

The power source is fundamental in any type of arc welding as it provides electricity needed to create an electric arc.

Types:

- Constant Current Power Sources (for SMAW) Constant Voltage Power Sources (for GMAW)

Features:

- Adjustable output current/voltage settings Portability features such as wheels or compact designs

2. Electrode Holder

An electrode holder allows you to grip electrodes securely while maintaining electrical conductivity.

Features:

- Insulated handle Secure locking mechanism

3. Protective Gear

Safety should never be compromised when performing any kind of welding work!

Recommended Gear:

Welders' helmet with appropriate shade lens Flame-resistant clothing Gloves designed specifically for welders Steel-toe boots4. Filler Rods/ Electrode Wires

These are essential components used in various techniques like TIG or MIG where additional material may be needed.

Specifications:

- Diameter varies based on project requirements.

Importance of Safety in Arc Welding

When engaging in any form of arc welding, safety must be priority number one! Here are some key practices that should always be followed:

Personal Protective Equipment (PPE)

Always wear appropriate PPE such as helmets with face shields to protect against sparks and UV radiation emitted during the process.

Ventilation

Proper ventilation is crucial when working indoors since fumes generated during welding can be hazardous if inhaled over prolonged periods.

Fire Prevention Measures

Ensure that flammable materials are kept at safe distances from your workspace, reducing risk factors associated with fire outbreaks during operations.

Mobile Welding Services in Phoenix

For those seeking convenience along with expert craftsmanship, look no further than mobile welding services available right here in Phoenix! Skilled professionals will come equipped with all necessary tools ensuring quality service at your location—be it residential projects like gates/fences or commercial jobs requiring heavy machinery repairs!

Benefits: 1) Time-efficient solutions without compromising quality. 2) Personalized consultations based on specific needs. 3) Accessibility across various locations within Phoenix!

Frequently Asked Questions about Arc Welding Techniques

Here are some common questions about arc-welding techniques answered concisely:

1) What is the difference between MIG and TIG?

MIG uses a continuously fed wire with shielding gas while TIG employs a non-consumable tungsten electrode often requiring manual filler addition—generally making TIG slower but offering better control over weld quality.

2) What are some common applications for SMAW?

SMAW is popular in construction sites due its versatility—commonly seen joining structural steel components or repairing vehicles/boats!

3) Can I perform mobile welding at home?

Absolutely! Many mobile services offer flexible arrangements where trained professionals come directly to your premises ensuring top-notch results without hassle!

4) Is there training required before attempting these techniques?

Yes! Formal training programs exist catering towards different levels—from beginner courses focusing on basic skills up until advanced certifications covering specialized areas such as aerospace applications!

5) How do I ensure my safety while working?

Always wear appropriate protective gear including helmets/goggles/gloves; maintain clear ventilation systems; establish fire prevention protocols within workspaces!

6) What kind of maintenance does my equipment need?

Regularly check connections/cables; clean nozzles regularly; ensure power sources function correctly—basically keeping everything tidy prolongs lifespan significantly!

Conclusion

Arc-welding techniques provide unmatched versatility when creating strong joints across various industries—from construction projects utilizing mobile services down through intricate metal fabrication works requiring precision craftsmanship! By choosing appropriate methods tailored towards specific needs whilst adhering strictly towards safety regulations ensures optimal results every time! So whether you're embarking on DIY endeavors at home or working professionally within manufacturing sectors—the world of arc-welding awaits you with endless possibilities ahead!